Leaving a deactivated pipeline in place is the safest option, reducing the risk of soil stability issues and avoiding major construction activities.

Line 3 Deactivation

The Line 3 Replacement Project, completed in October 2021, was an integrity and maintenance driven project. Now that the replacement pipeline (Line 93) is operational, the existing Line 3 has been permanently deactivated in place. Enbridge is responsible for its pipelines, whether they are active or not. Enbridge will continue to monitor the deactivated pipeline and maintain the right-of-way.

Should a landowner choose to have the line removed from their property, Enbridge will do so with an unwavering commitment to safety.

Deactivation facts

- Independent engineering research and analysis, as well as historical knowledge of out-of-service pipelines, have determined that deactivated pipelines with adequate cover will have a very long remaining life as load-bearing structures, even after many decades of deactivation. Enbridge will continue monitoring the right-of-way and mitigate concerns related to our pipeline should a need develop that impacts public safety, the environment or land use.

- Environmental regulatory requirements prohibit altering current hydrology. Therefore, the Line 3 deactivation process will protect water resources to ensure that the deactivated pipeline will not drain any fields, lakes, rivers, streams or other wetland areas.

- Enbridge has a vested interest in ensuring that any deactivated pipeline does not compromise land use or the integrity of the other pipelines that share the right-of-way.

- Enbridge will continue to operate the existing pipeline safely while the new pipeline is installed, because refineries in the Midwest served by the pipeline rely on continuous deliveries of crude oil to provide the gasoline, heating oil, and other products that we use every day.

The deactivation process

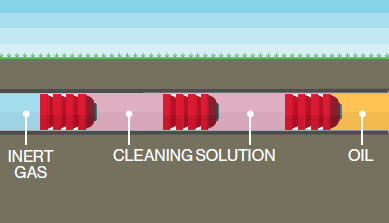

1. Remove the oil from the pipeline: The pipeline is purged of product using an inert gas.

2. Clean the pipeline: A combination of pipeline cleaning tools (known as "pigs") and cleaning solutions are used to wipe and clean the pipelines.

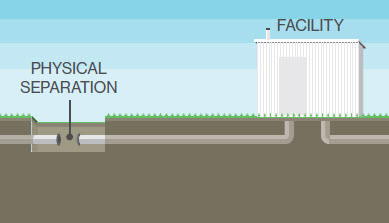

3. Disconnect the pipeline: The pipeline is physically disconnected and sealed off from the active operational facilities.

4. Monitor the right-of-way: The pipeline will continue to be monitored with regular pipeline patrols, pipeline signs indicating location, depth-of-cover surveys and inclusion in Call/Click Before You Dig programs.